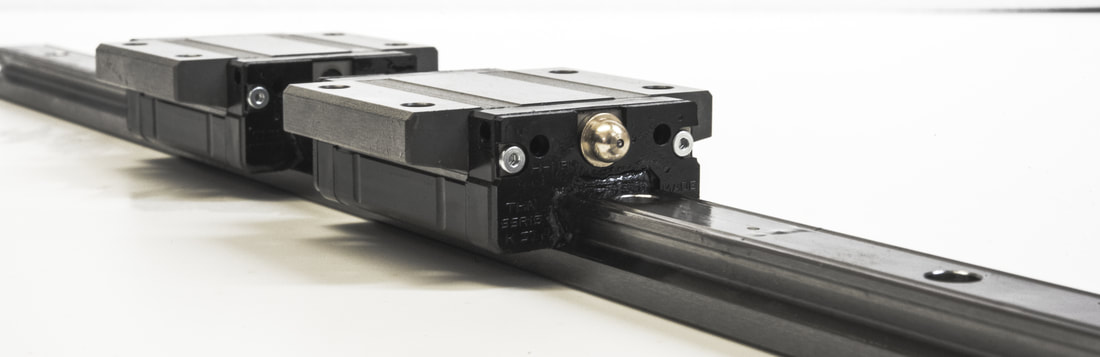

CNC Mini-Mill/2Introducing the Minitech CNC Mini-Mill/2, a recently re-designed and improved CNC milling machine that offers affordability and high-quality performance for small part manufacturing. Built from the ground up with precision in mind, our Mini-Mill/2 features linear bearings and precision ball-screws at every stage, ensuring optimal results. Each base and column is meticulously machined from solid billet stock, guaranteeing durability and accuracy.

Proudly manufactured by Minitech in the USA, our CNC Mini-Mill/2 has undergone a recent redesign to enhance its capabilities and user experience. With worldwide distribution available, this versatile machine can be customized to meet your specific needs. Discover the power of the Minitech CNC Mini-Mill/2 and experience its unmatched precision, reliability, and flexibility in one compact system. Machined from billet aluminum stock for superior strength and rigidity.

|

Minitech Machinery Corp. 6050 Peachtree Parkway Suite 240-205 Norcross, Georgia 30092 USA(770) 441-8525 [email protected] |

|